Lime Production Line Description

FTL Machinery is committed to providing comprehensive solutions for the production of active lime. We have active lime production lines with a capacity of 100 to 1,000 tons per day, covering the three mainstream processes of rotary kilns, shaft kilns and double-chamber kilns.

All of our production lines adopt advanced technologies and have a high degree of flexibility in raw materials and fuels. The active lime produced has high activity and stable quality, and is recognized as a high-quality raw material in industries such as steel and alumina.

No matter which type of kiln you choose, FTL Machinery can provide a one-stop full range of services from raw materials to finished product output, including engineering design, equipment manufacturing, civil construction, installation and commissioning, personnel training, as well as engineering general contracting of main and auxiliary facilities.

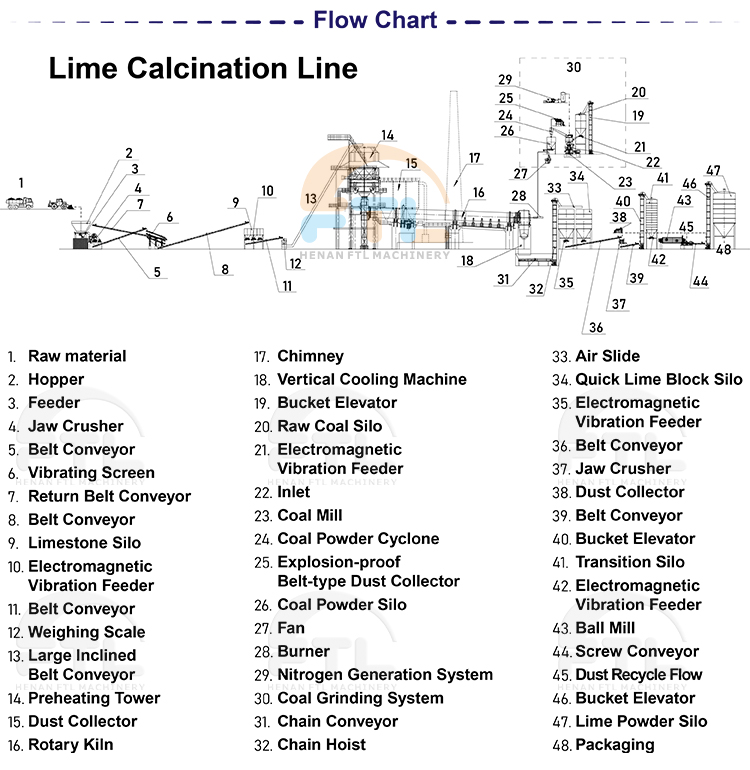

Rotary kiln process

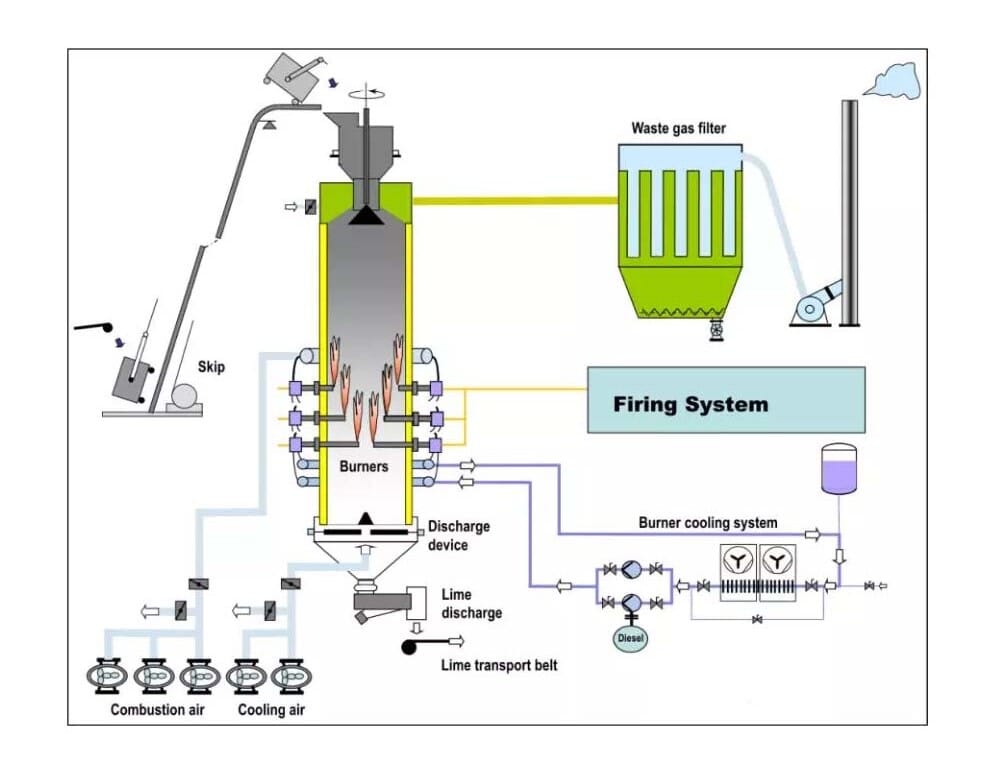

Vertical kiln process

Detailed Images of Lime Processing Plant Site

hydrated lime production line

FAQ of Lime making line

1. How is the quality of your products?

Our products are manufactured strictly according to national and international standard, and we take a test on every machine before delivery.

2. Guaranteed:

During warranty period, we will be responsible for all damages, including wearing parts, human damage, etc.

3. How about price?

Yes, we are factory and are able to give you the best price.

4. Service and Payment Terms?

A. We usually accept T/T, L/C, but other terms also workable.

B. We take pictures of finished products before delivery.

5. Will you help with installation and staff training?

Yes, we can send our engineers to your place to guide the installation and train your workers if needed, but the buyer should bear our technician’s round tickets, accommodation, and food